The Importance of Clearing Branches from High-Voltage Lines

In modern power grid systems, removing tree branches from high-voltage lines is critically important. Statistics show that branch-related outages make up a large portion of annual power disruptions. For example, a 2019 study revealed that roughly 20% of all outages occurred when trees touched power lines. These incidents don’t just disrupt electricity supply—they also create serious public safety risks. When high-voltage lines fail, they can trigger fires, damage equipment, and cause significant economic losses. For these reasons, keeping power lines clear is essential for both grid stability and community safety.

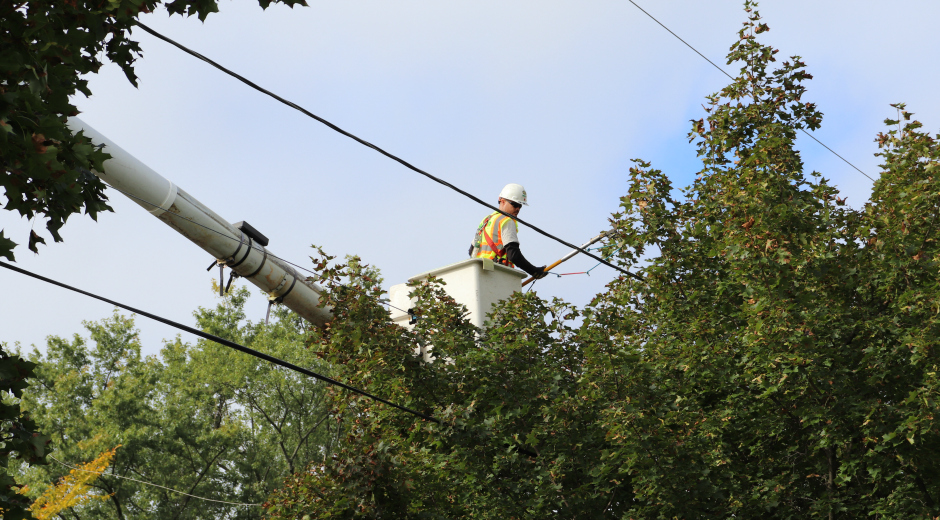

Traditional methods for clearing branches—like manual trimming or mechanical cutting—face multiple challenges. First, manual work is slow, labor-intensive, and dangerous. Workers often operate at great heights, exposing them to severe injury risks. Second, mechanical tools struggle in rough terrain or bad weather and can harm the environment. For instance, heavy machinery might damage nearby vegetation or disturb wildlife habitats. These limitations highlight the need for safer, more efficient solutions.

This is where laser-based systems come into play. By using focused laser beams, these devices can remove branches quickly and precisely without direct contact. This approach minimizes risks to workers, reduces environmental harm, and prevents outages more effectively than older methods.

Advantages of tree trimming with laser obstacle remover

Laser systems address many shortcomings of traditional techniques. For example, they allow operators to cut branches from a safe distance, eliminating the need for climbing or risky maneuvers. Additionally, lasers work in almost any weather, ensuring consistent performance during storms or extreme temperatures. Most importantly, this technology avoids physical contact with power lines, significantly lowering the chance of short circuits or equipment damage.

Economically, laser systems help utilities save money over time. Faster cleanup reduces grid downtime, while fewer outages mean lower repair costs and less lost revenue. Environmentally, the precision of lasers minimizes collateral damage to surrounding trees and ecosystems. In short, this technology offers a balanced solution that prioritizes safety, efficiency, and sustainability.

Limitations of Existing Clearance Methods

While current approaches like manual trimming or helicopter-assisted cutting have been useful, they face clear drawbacks. Let’s break these down:

Manual Pruning: This method requires large teams working in hazardous conditions. Data shows that injuries during high-voltage line maintenance remain alarmingly common. Even with safety gear, workers face risks from falls, electrical shocks, or falling debris.

Helicopter Operations: Although helicopters cover large areas quickly, they’re expensive to deploy and heavily weather-dependent. Rain, fog, or high winds can ground flights for days, delaying critical maintenance. Helicopters also produce noise pollution and carbon emissions, conflicting with environmental goals.

Environmental Impact: Traditional tools like chainsaws or chemical treatments often harm non-target plants and wildlife. For example, herbicides might seep into groundwater, while machinery vibrations disturb animal habitats.

These challenges underscore why the power industry needs better solutions. Laser systems, with their remote operation and precision, provide a promising alternative.

Design Principles of Laser Obstacle Remover Systems

Balancing Safety and Efficiency

When designing laser clearance devices, engineers focus on two priorities: operational safety and cutting speed. The equipment must remove obstacles like branches quickly while protecting both grid infrastructure and operators. To achieve this, modern systems include features like:

Real-time monitoring cameras and sensors to track laser positioning.

Automated shutoff mechanisms that activate if the beam veers off target.

User-friendly interfaces to simplify training and reduce human error.For instance, advanced visual systems let operators adjust the laser’s path remotely, ensuring accurate cuts without approaching live wires. By integrating these safeguards, the technology minimizes accidents while maintaining high productivity.

Improving Speed and Precision

To maximize efficiency, engineers optimize two key components: the laser’s power output and its focusing system. Tests show that fine-tuning these elements can reduce clearance times by up to 40%. For example, upgrading a laser’s optical lenses might allow it to burn through a 10 cm-thick branch in 30 seconds instead of a full minute.

Additionally, smart software plays a vital role. Image recognition algorithms automatically detect branch size, distance, and density, then calculate the optimal cutting path. Some systems even use AI to “learn” from past operations, steadily improving their accuracy.

Environmental and Sustainability Benefits

Laser systems align closely with modern environmental goals. Unlike older methods, they:

Avoid toxic chemicals (e.g., herbicides).

Produce no physical waste like wood chips or oil leaks.

Use energy efficiently, often drawing power from renewable sources.A practical example: When clearing branches near rivers, lasers prevent chemical runoff that could pollute water supplies. They also spare nearby trees from unnecessary damage, helping preserve local ecosystems.

Wildlife Protection Features

Designers pay special attention to minimizing harm to animals. For example:

The laser’s 1080nm wavelength reflects harmlessly off bird feathers and insect exoskeletons, causing no burns.

Slow-moving beams give creatures time to flee—unlike sudden mechanical noises that startle them.

Operators can pause work instantly if protected species (e.g., nesting birds) are spotted nearby.

Cost-Effectiveness and Long-Term Value

While another advantage of tree trimming with laser is that they save money over time. Key advantages include:

Reduced labor costs (fewer workers needed).

Lower equipment maintenance (no chainsaw blades to replace).

Fewer outage-related fines or compensation payments.

For example, a utility company might spend $50,000 on a laser unit but save $500,000 annually in manual labor and outage repairs.

Conclusion

Portable laser obstacle clearance systems represent a major leap forward for power grid maintenance. Advantages of tree trimming with laser are are worth noting. By combining safety, speed, and environmental care, they address the core challenges of traditional methods. As technology advances, these devices will likely become smaller, cheaper, and even more efficient—ensuring reliable electricity supply while protecting both people and the planet.

PORTABLE 250W Laser Obstacle Remover

Tree-Trimming Work Underway to Help Prevent or Minimize Power Outages in Maryland

The image is from the above network connection

Traditional methods may lead to cutting failure, vehicle congestion, high-altitude danger, and inconvenient time management.